Features & Benefits

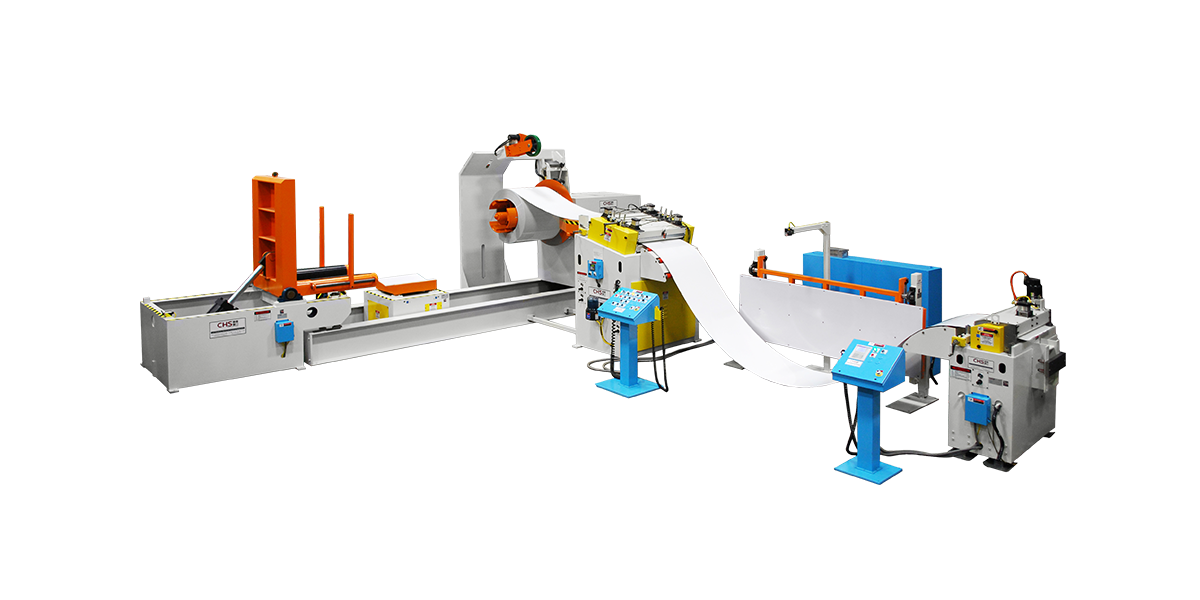

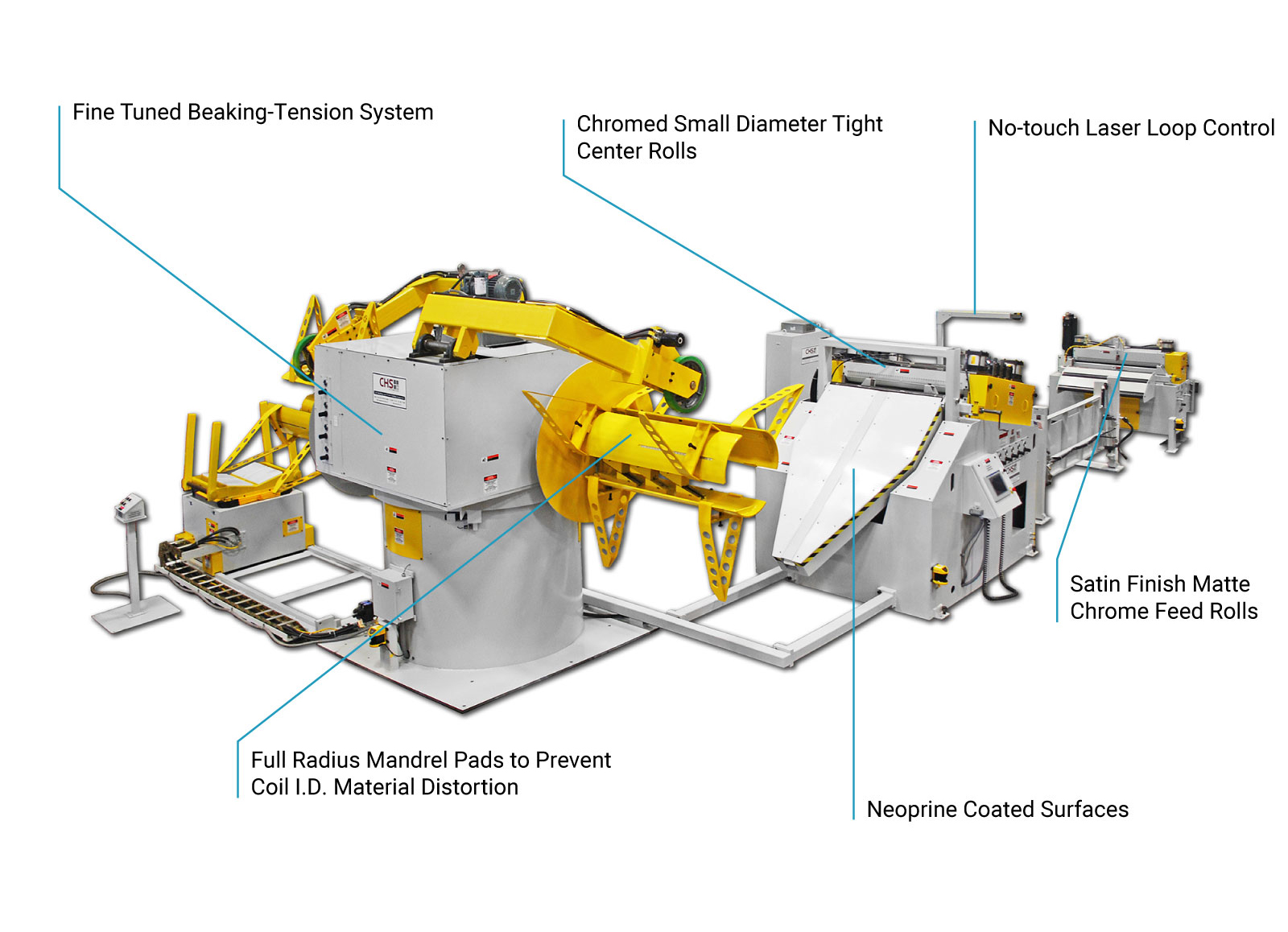

- Specialized designs and features for un-coiling and processing pre-painted, Class A and delicate materials.

- Features include non-marking surfaces, chrome rolls, improved roll geometry.

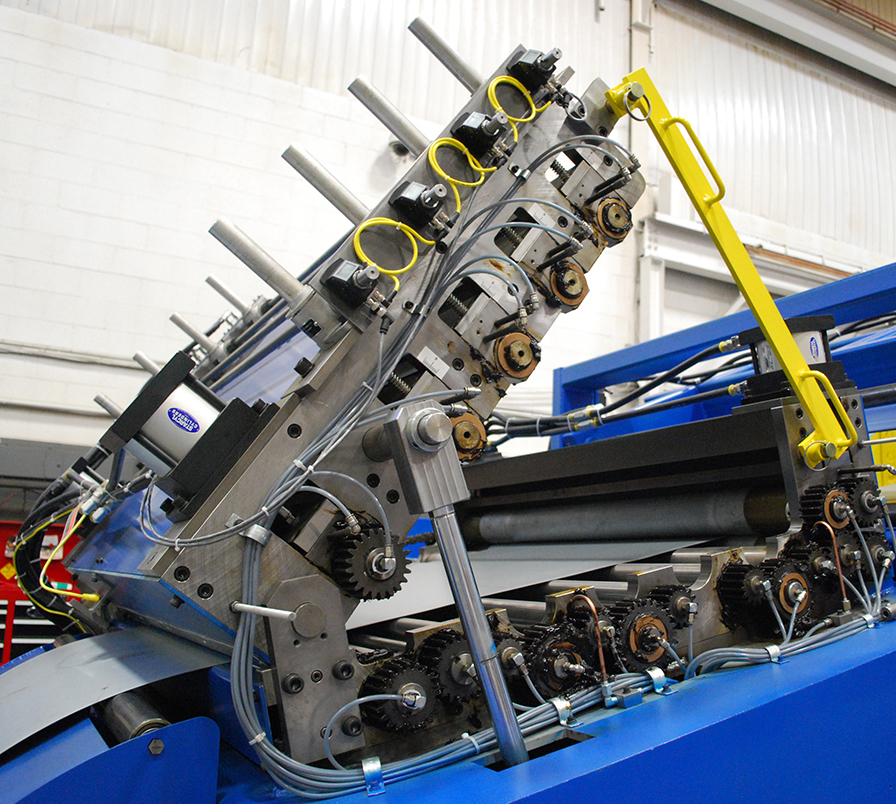

- High lift open straightening heads for roll cleaning.

- Improved fine tune adjustments for braking tensions, cylinder pressures, roll position and stock threading.

- Servo control technology driven acceleration and decelerations to prevent material marking.

Specifications

- Coil capacity range 4,000 Lbs. – 60,000 Lbs.

- Coil width capacity range: 12” – 84”

- Stock thickness ranges: 0.010” – 0.250”

- Higher straightening roll config for improved flatness

- Recipe driven roll settings and memory – optional

Highlights

Control & Fluid Power Technologies

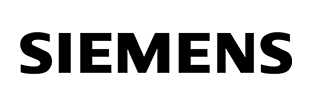

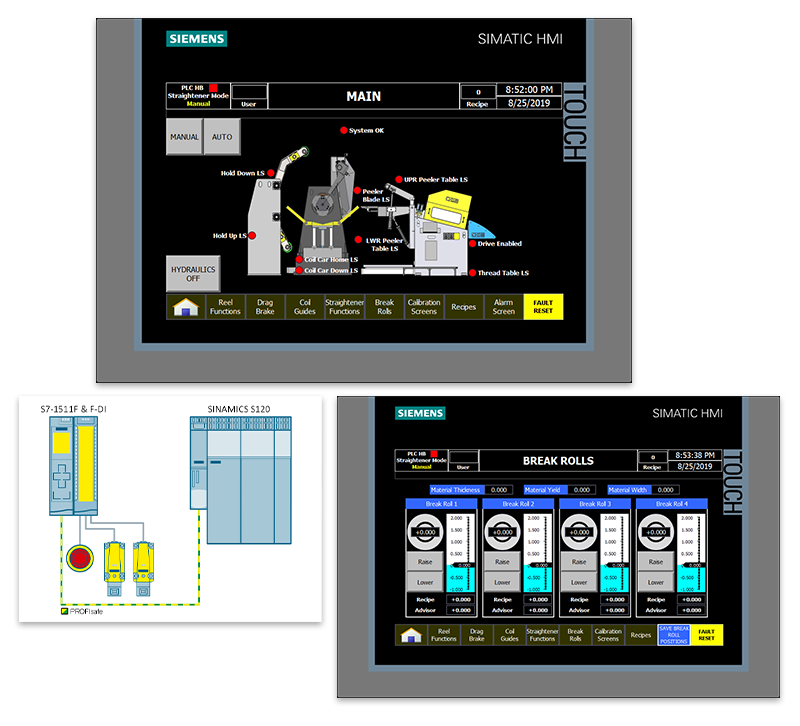

- CHS – Advanced Control System Platforms

- Hi Quality Component Partners

- Intuitive Operator HMI And Consoles

- Smart Technology Connectivity, I/O

- Optional- Integrated Safety STO, SLS

Have Questions?

CHS Automation Has the Answers & Solutions!

Our industry has drastically changed over the past few years. This is mostly related to new steels that have been created to help take weight out of automobiles to help increase gas mileage, among other innovations. As a result, knowing the technical terms associated with these advancements has become increasingly difficult.

Here are just a few examples of technical keywords associated with these advancements:

1200 MPA

HSLA

SERVO PRESS

80 KSI YIELD

AHSS

PENDULUM MODE

100,000 PSI

ALUMINUM

…AND MORE

With this in mind, it’s more difficult than ever to keep up with the physics and design requirements needed to process these types of materials reliably. If the following words are foreign to you, let’s talk. We’ll gladly help figure out exactly what sort of machinery you require for your job.