The Industry Standard

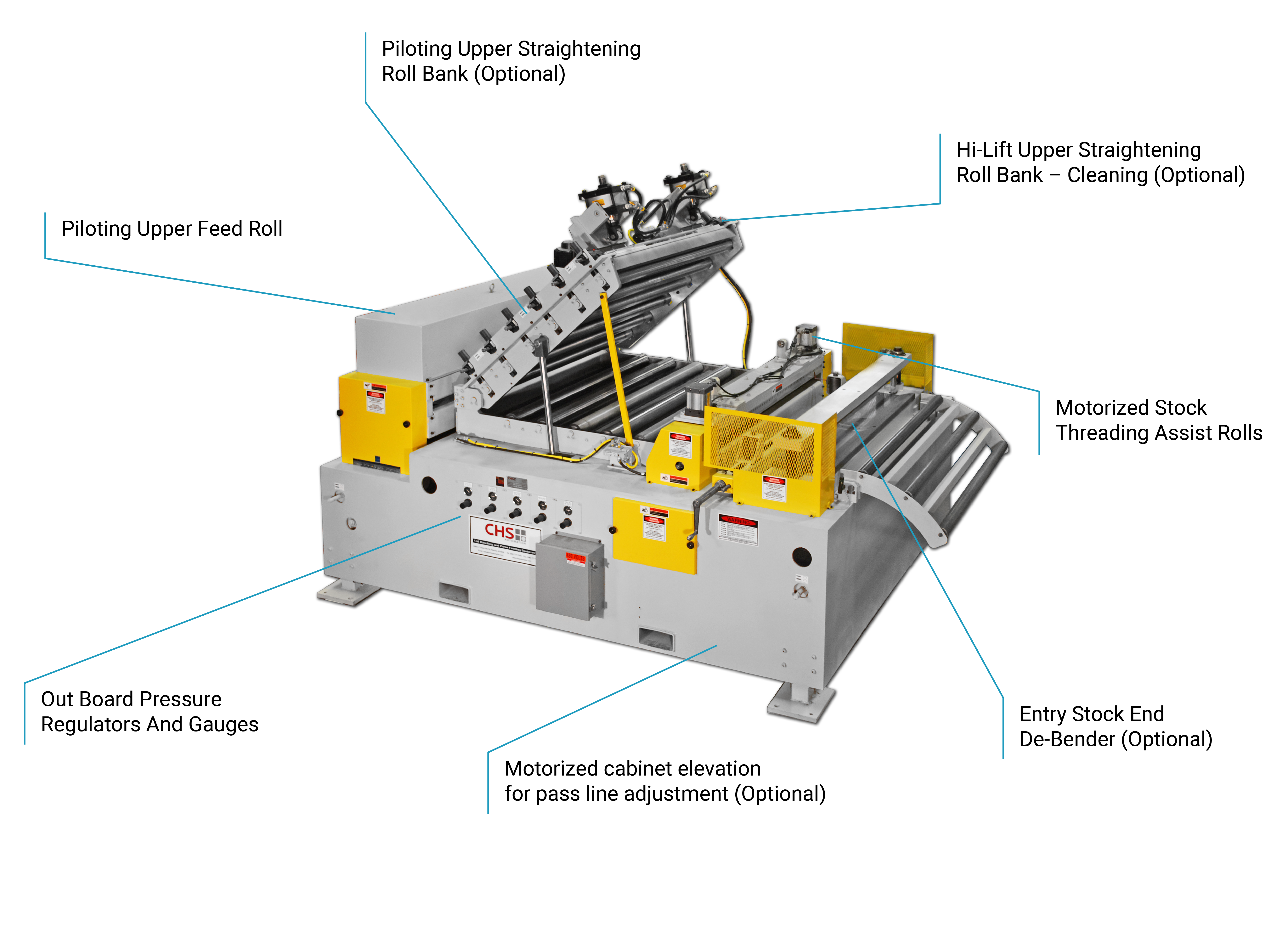

Nidec CHS Feeder–Straighteners are built to handle up to .500” thick materials with stock width capacities ranging from 6” – 84”. These machines are accurate, durable and often times an economical way to integrate straightening into press automation.

Standard Features

• Matte #3 Chrome Blast Roll Finish

• Fixed Press Mount Attached Bracket

• High Performance Servo Motor

• Cluster Geared Drivetrain

• High Speed Air Pilot Release

• Centralized Lubrication Block

• Catenary Loop Support Section

• Single Roll Quick Adjust Edge Guides

• 4-Button Remote Hand Pendant

• End of Stock Detector

• 200 Job Recipe Storage

• Color HMI Touch Screen

Features with Pull Through Straightener PTS-225-5

• Manual Entry Pinch Rolls

• 2.25″ Diameter Work Rolls

• 2 Over 3 Configuration

• Independent Work Roll Adjustment

Features with Pull Through Straightener PTS-300-7

• Air Operated Entry Pinch Rolls

• 3.00″ Diameter Work Rolls

• 3 Over 4 Configuration

• Independent Work Roll Adjustment

Optional Features

• Cabinet Base Free Standing +/-6″

• Motorized Passline Adjustment

• Catenary Entrapment Roll

• Hand Crank Edge Guides

• Anti Back Up Roll

• Material Support Table

• Allen Bradley Controls

• Siemens Controls

• PMC Minster Press Integration

• Enhanced SLS/STO Control

• Custom Paint Color

Options with Pull Through Straightener PTS-300-7

• Digital Readouts for Work Roll Depth

• Pilot Release Straightening Head

• Powered Entry Pinch Rolls