Featured Remanufacturing Projects

From presses to feed lines to single components, NP&A has remanufacturing packages to meet all unique needs

With dedicated remanufacturing facilities and trained personnel on three continents, Nidec Press & Automation can provide new life for used machinery. NP&A has the unique combination of decades of experience and world-class facilities around the globe to remanufacture your pressroom equipment.

From presses and major components to complete coil lines, the Nidec Press & Automation group of companies is your single source for a wide-ranging offering of machinery remanufacturing services for the metal forming industry.

Machinery remanufacturing can be completed at any of the NP&A production facilities dedicated to remanufacturing. In addition, NP&A offers an extensive inventory of used metal forming machinery that has been remanufactured to OEM specifications and is available for quick delivery and competitive prices.

NP&A backs up its quality remanufacturing work with an industry-leading parts and labor warranty, and a responsive global Customer Service network.

For detailed information about NP&A’s remanufacturing services click on the links below:

Minster Presses & Components

With more than 125 years of manufacturing experience, Nidec Minster has been remanufacturing presses and press components for more than 70 years.

Take full advantage of the productive potential in your older Minster presses. Have them remanufactured and their performance enhanced with the latest techniques and equipment. And don’t compromise the results. To truly remanufacture your Minster, bring it back to the people who built it in the first place… bring it home to Minster.

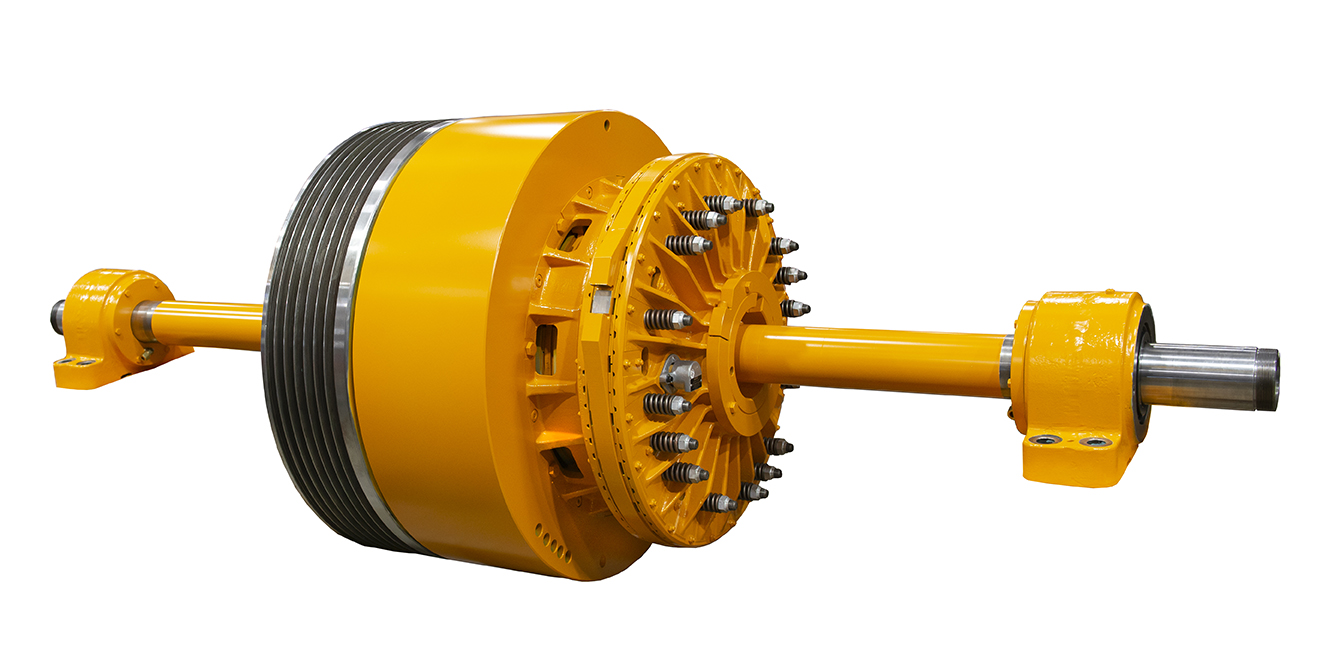

Minster specializes in the rebuilding of press component assemblies as well as the entire machine. Common candidates for this process are slide assemblies, clutch assemblies and counterbalances.

Make Your Press Better Than New

With tremendous press engineering capability at its disposal, Minster has the ability to modify your press to better meet your current needs. These modifications may include changes to the press’ original specifications and/or incorporating newer technologies into your older press. Depending on your press type and its condition, potential modifications include:

• Increased Energy Ratings

• Stroke Change

• Shutheight Change

• Increased Speeds

• Reduced Stopping Times

• Control Upgrades

Standard Minster Press Remanufacturing Process Includes:

1. Complete press tear-down

2. Cleaning and inspection of all parts and comparing them to original specifications

3. Re-machining of crown bearing bores, connection bores, gibs slide and bolster as required to meet specifications.

4. Replacement of all bronze bushings, bearings, oil seals, packing and other wear items.

5. Installation of a new lubrication system

6. Installation of a new pneumatic system

7. Upgrading to the latest safety requirements

8. Supply of a new, updated service manual

9. Retention of a permanent record for the life of the remanufactured equipment

10. 24/7/365 emergency parts and service response.

Nidec Minster recently opened a 25,000 sq. ft. addition dedicated to repair parts machining and remanufacturing. In addition, the NP&A Service Center in Queretaro, Mexico has expanding with a new facility that will not only increase its warehouse for common repair parts, but will also greatly increase capabilities for remanufacturing larger Minster presses on site.

You Have Our Guarantee

We back up our promise of quality with a parts and labor warranty that is unequaled in the industry. New mechanical components are covered for a full two years, and new electrical, pneumatic, and hydraulic parts are warranted for one year.

Coil Line & Components

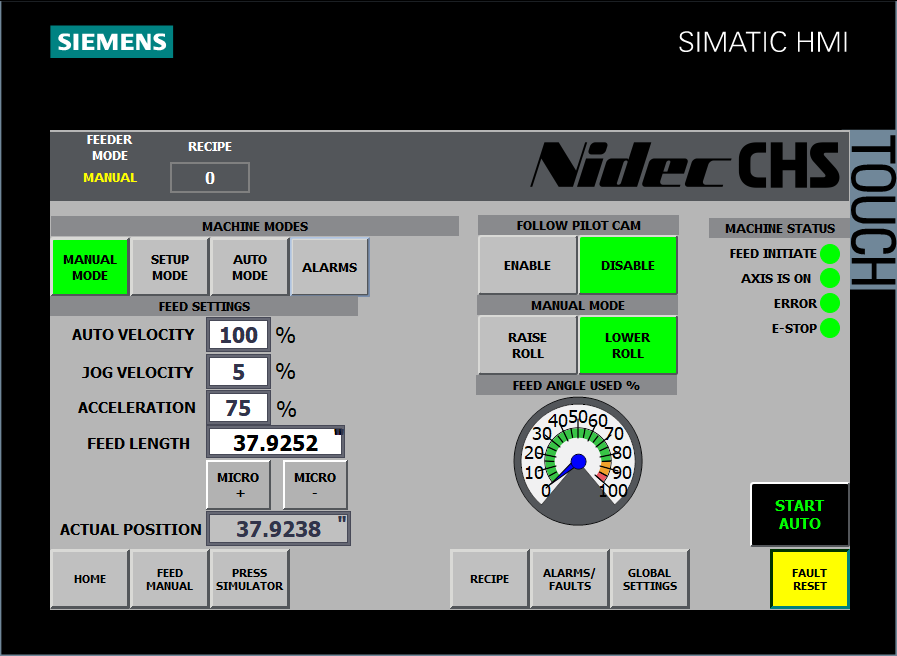

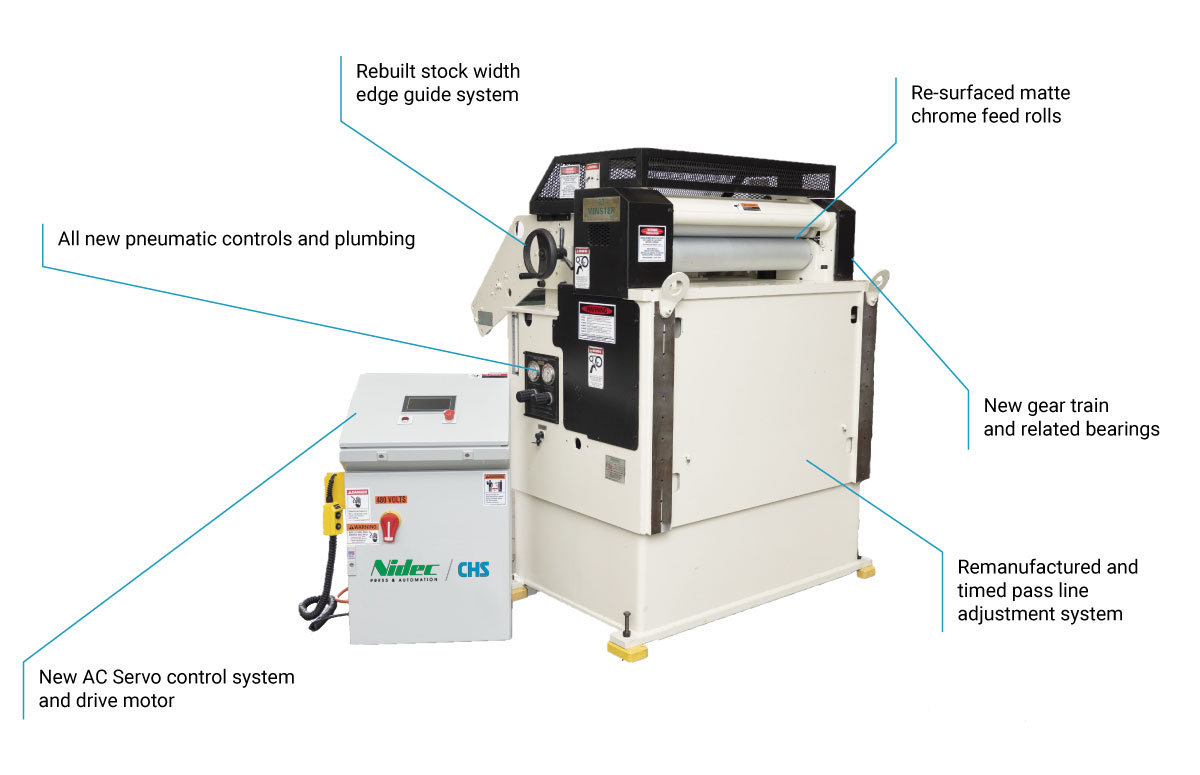

Nidec CHS offers complete remanufacturing services for coil feed lines and press automation. We have the capabilities to bring existing equipment back to OEM mechanical specifications. In addition control and fluid power systems are modernized to today’s standards.

From complete and integrated coil lines to individual components, Nidec CHS will custom remanufacture a wide range of coil line brands and machinery sizes to fit the application and budget desired.

Benefits & Features:

Modernized AC Control Systems

Intuitive Operator Interface

Optimization – Strokes Per Minute

Increased Accuracy And Repeatability

Remanufactured coil line projects often include updating to the latest technology, including controls, software and integration possibilities.

Contact the experts at NP&A for a custom solution to upgrading your coil line.

Standard Remanufacturing Process Includes:

Step 1

EVALUATION

Each machine component is thoroughly inspected and evaluated for condition and required repairs

Step 2

SCOPE DEFINED

Machine specific plans of action are detailed and documented. Including mechanical, fluid power and controls

Step 3

THE WORK

Replacement parts installed, repairs performed, fabrication, re-assembly and finished with custom paint schemes

Step 4

QUALITY AND RUN-OFF

A very rigorous quality check list is completed and documented. Production simulation run off is performed, prior to shipment

High Speed Presses

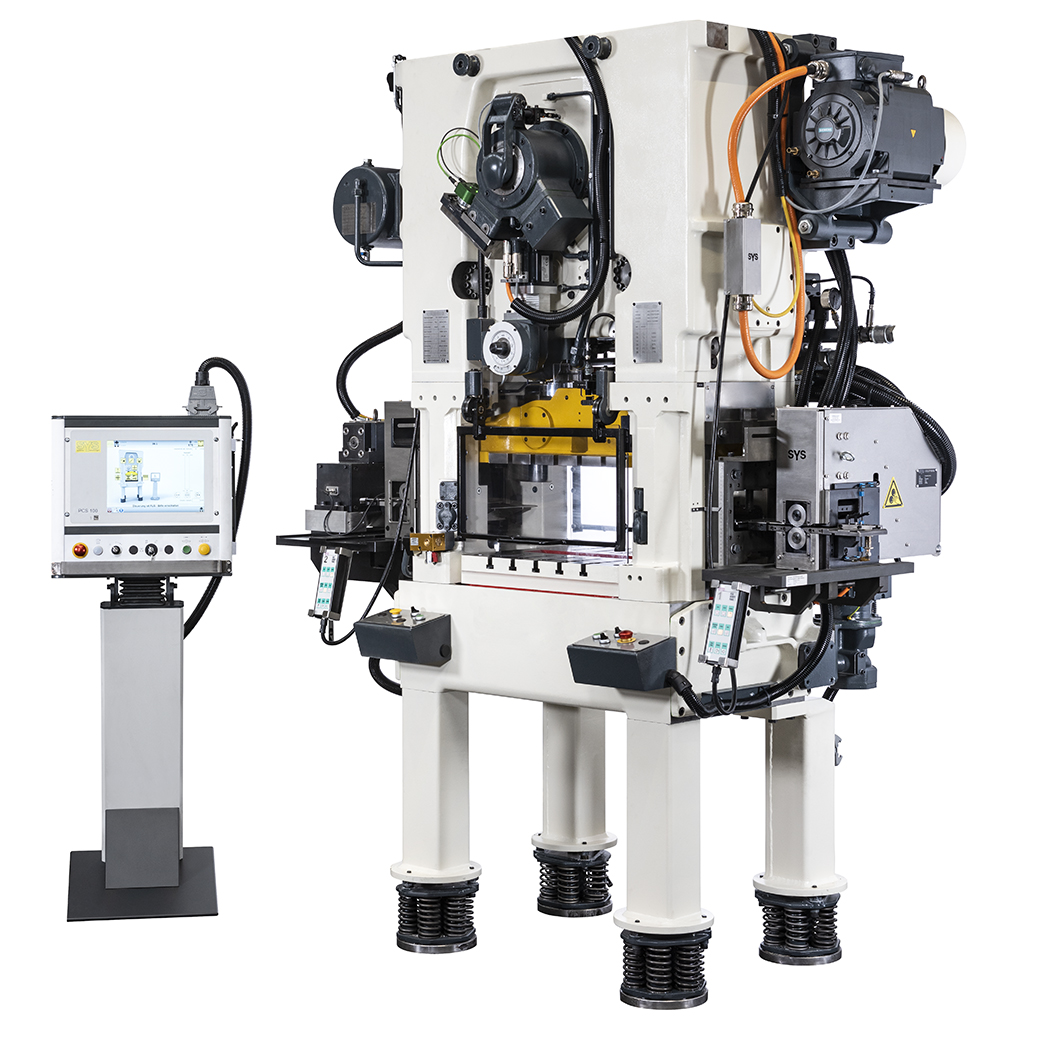

With decades of experience and knowledge, Nidec SYS has the capability to partially or completely remanufacture high speed presses. Increase the lifespan of existing equipment and make the most of your investments by remanufacturing anything from a single component to the complete machine.

Benefits to remanufacturing high speed press with SYS include:

• Efficient solutions to modernize technologies and expand capability/capacity without the purchase of new equipment

• Remanufacturing solutions targeted to your unique need

• Global facilities for remanufacturing available to locally and efficiently complete your service work

• High speed expertise

• Ability to integrate with SYS Control upgrades

How can we help you? Please contact us at a location near you to begin the discussion:

Global Corporate | +1(419) 628-6000 | CustService@nidecpa.com

Americas Region

Minster, OH, USA

(419) 273-6367

CustService@nidecpa.com

Pittsburgh, PA, USA

(412) 785-1993

vamcoservice@vamco.com

Macomb, MI, USA

+1(586) 777-7440

CustService@nidecpa.com

Querétaro, Mexico

+52 442 253 1671

service.mexico@nidecpa.com

São Paulo, Brazil

+55 11 5071-0015

andre.sellanes@nidecpa.com

Europe/Mid-East/Africa Region

Navarrete, Spain

+34 941 287521

service@arisa.es

Peiting, Germany

+49 8861-71360

Service.emea@nidecpa.com

Grafenau, Germany

+49 8552 96 39-0

service@nidecsys.com

Asia Pacific Region

Kyoto, Japan

+81-75-283-3902

npaservice-shimpo@nidec.com

Pinghu, China

+86-573-8507-8727

nkcp.service@nidec-kyori.com

Shanghai, China

+86 138 1764 4654

vmsales@vamcointernational.com