JAE Oregon and Nidec Kyori — a

Connection 35 Years in the Making

From its beautiful tree-lined campus in the Pacific Northwest, JAE Oregon has established a vertically integrated operation for producing world class connectors, primarily for the automotive market.

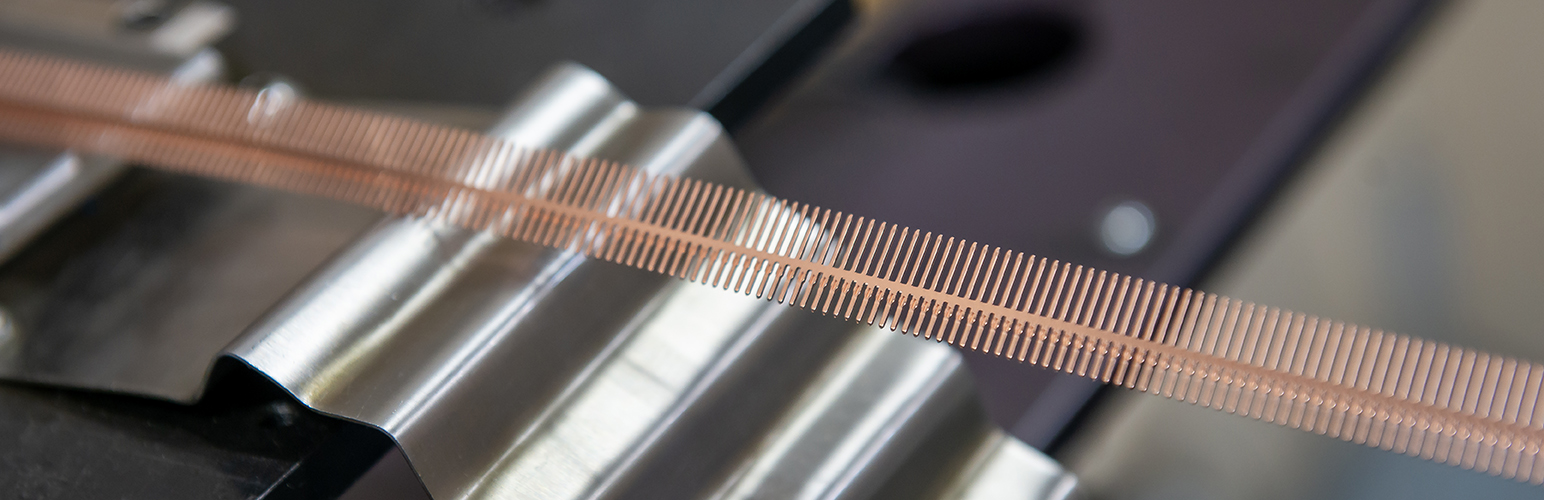

“If you reach underneath the seat of your car, pull down the wire harness that’s there, all the bits that look like Legos on the end of cables, that’s what we’re doing here,” said Jahvon Hammond, Director of Manufacturing Engineering for JAE Oregon. “We make the full connectors here. We do progressive stamping, injection molding, electroplating, CNC milling, automated assembly, and then some manual assembly.”

JAE Oregon is a division of JAE Aviation Electronics Industry, Ltd. located in Tokyo, Japan. Founded in 1953, JAE is a global supplier of a wide range of connectors and electronics with more than 10,000 employees at 29 worldwide locations.

JAE Oregon was established in 1988 in Tualatin, Oregon, just north of Portland.

High speed stamping is one of the core processes at JAE Oregon, which operates 10 Nidec Kyori presses to stamp up to 100 million terminals a month to be assembled into connectors on site or delivered to internal or external customers. Depending on business conditions JAE assembles anywhere from 40 to 70 million connectors a year.

The relationship with Kyori presses began when the Oregon facility was founded more than 35 years ago. Chief Engineer at JAE Oregon, Katsumi Arai explained that Kyori presses were utilized when stamping operations began in Japan more than 40 years ago. Pleased with the quality of the Kyori presses and wanting to utilize already-established progressive dies, Kyori presses were purchased for the start-up of the Oregon plant.

“The Kyori presses are very reliable machines. They’ve survived,” Hammond said. “We have machines that are more than 30 years old, so now we’re just beginning to replace some of those legacy units. We replaced a couple within the last couple of years and we’ve got plans to pretty much continue replacing them one by one.”

Kyori ANEX-40IIW presses are two of the most recent additions at JAE Oregon. The knuckle link design of the ANEX series presses eliminates thermal displacement resulting in precise bottom-dead-center repeatability. In addition, the design contributes to greater durability, longer die life and reduced noise and vibration. The ANEX-40IIW presses also feature wide (950mm, 37.4inch) beds which help to facilitate the multi-station progressive dies at JAE Oregon.

“Stamping is one of our three core processes here at JAE Oregon, along with CNC milling and electroplating,” Hammond said. “Because a lot of facilities do not have the electroplate capabilities, it’s a very big competitive advantage that we have. We are an A-to-Z solution. We can make a connector from the ground up, and that separates us from a lot of our competition.”

Nidec Kyori is part of the Nidec Press & Automation group of companies, offering a wealth of integrated manufacturing solutions from high speed feeds to coil lines to complete automation systems. In addition, NP&A offers a highly responsive global network of customer service and technical support.

“I think what’s kept us engaged with Kyori and Nidec is the strong communication,” Hammond said. “It’s the strong relationship from the headquarters side as well as the strong support we seen here in Oregon with Minster and the other groups as well.

“One of the exceptional things has been the service from the Nidec team and the Kyori group,” he continued. “They have flown technicians in from Japan to help us out, and help educate our maintenance team and our engineering staff on how to better maintain the presses, keep them running, and how to make fine tweaks to the machines to keep them running in top condition. It’s more of a partnership. We truly get a partnership with Nidec and the Kyori group which we appreciate.”

Most of JAE’s current press processing is performed on high-speed machines, and JAE aims to expand its capabilities further by utilizing the newly introduced Kyori press machines.

“Primarily we’ve been automotive, but as we continue to consider new business we want to push those boundaries even more,” he said. “We’ve been involved with the rail car industry, and we’re also getting involved in some aerospace and charging harnesses for EVs.”

“We are committed to improving OEE, or Overall Equipment Effectiveness, and are working hard to achieve this goal,” Hammond added. “We are implementing improvement activities throughout the company with the aim of reaching world-class standards. Replacing some of the older machines with new Nidec Kyori models has significantly improved the operation of our presses and dies, contributing to higher OEE. Our challenge continues as we strive to maintain global competitiveness.”

To learn more about JAE Oregon, its products and value-added services, visit the company online at: www.jae.com/en/oregon.